Hydrogen will be instrumental in the global shift towards an emission-free future. Fuel cells, being the most developed technology, are essential for its worldwide deployment. Their attractiveness is amplified by the growing surplus of electricity generated from renewable energy sources at both the residential and national levels. This surplus facilitates the broader adoption of fuel cells, as hydrogen storage proves to be considerably more economical than battery storage for both individual residences and grid-level applications.

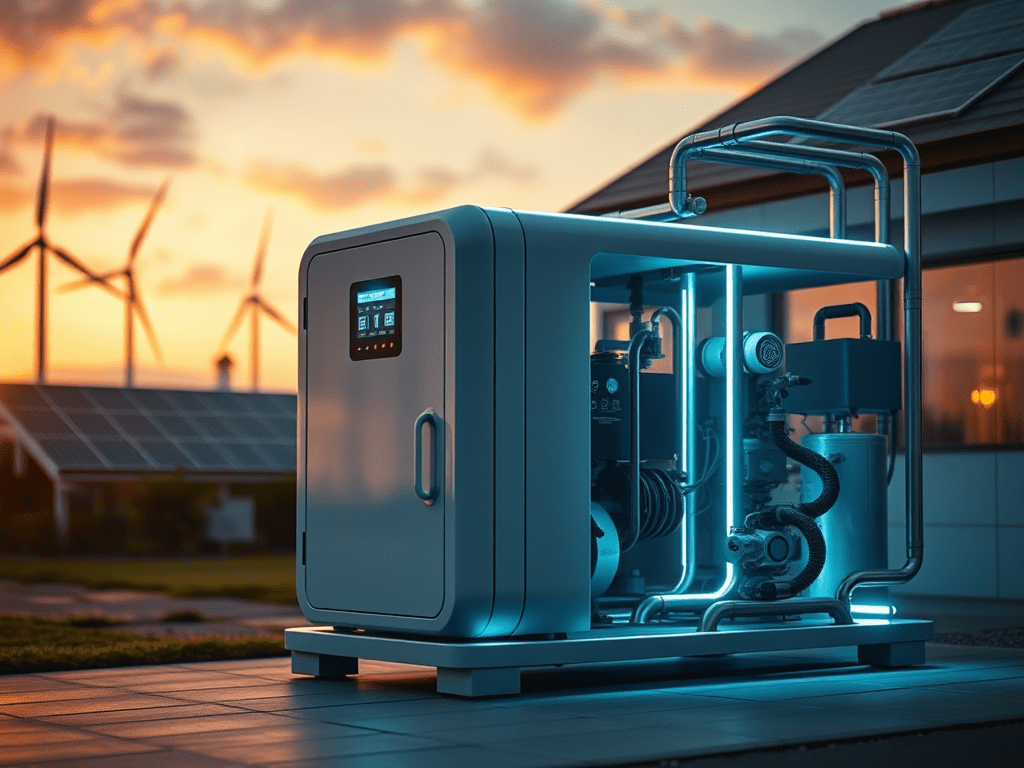

Hence, if surplus electricity is available, water electrolysis is the preferred method due to its spatio-temporal flexibility. Converting water to hydrogen requires an electrolyzer. A 100% efficient electrolyzer demands approximately 39 kWh of electricity to produce 1 kg of hydrogen, while current devices use around 48 kWh/kg. Once hydrogen is produced, storage becomes the next hurdle. Options include storing hydrogen as pressurized gas, liquefied hydrogen, or in metal/organic hydrides. For pressure storage, the future lies in electrochemical hydrogen compressors over traditional compressors. Once stored, hydrogen can be converted to power by a fuel cell, typically generating over 35 kWh per kg of hydrogen consumed. However, there will be some power loss associated with the storage system.

An optimal system would employ a regenerative fuel cell linked to an electrochemical hydrogen compressor with a Type VI or Type V hydrogen tank. The ideal configuration would include compressor and fuel cell membranes crafted from organic polymers derived from biochemicals. Achieving this necessitates three areas of R&D:

- Identification and production of base biochemicals that can be converted into polymer membranes.

- Enhancing the efficiency of the fuel cell to operate in both modes.

- Developing Type VI and Type V hydrogen tanks made entirely of biopolymers derived from biochemicals.

Regenerative Fuel Cells

Regenerative fuel cells are a type of fuel cell that can operate in both fuel cell mode and electrolysis mode. In fuel cell mode, they generate electricity by combining hydrogen and oxygen, producing water as a byproduct. In electrolysis mode, they use electricity to split water into hydrogen and oxygen. This dual functionality makes regenerative fuel cells highly versatile and suitable for various applications, including energy storage, backup power, grid stabilization and residential power.

The development of regenerative fuel cells with organic polymer membranes derived from biochemicals is a key area of research. Organic polymers offer several advantages, including flexibility, durability, and the potential for lower production costs. By utilizing biochemicals as feedstock for polymer production, the environmental impact of fuel cell manufacturing can be further reduced, contributing to the overall sustainability of the hydrogen economy.

Electrochemical Hydrogen Compressors

Electrochemical hydrogen compressors mark a notable improvement in hydrogen storage technology. These compressors employ electrochemical reactions to compress hydrogen, resulting in greater efficiency and lower energy consumption than mechanical compressors. Furthermore, with fewer moving parts, they necessitate less maintenance than conventional compressors.

Type VI and Type V Hydrogen Tanks

Type VI and Type V hydrogen tanks represent cutting-edge advancements in hydrogen storage technology. These tanks are designed to store hydrogen at high pressures, delivering higher energy density and improved safety compared to earlier models. Type VI tanks are fully composite with a polymer liner, while Type V tanks are fully composite without a liner. Both types are lightweight and durable, making them suitable for a range of applications, including transportation and stationary storage.

The development of Type VI and Type V tanks made entirely from biopolymers derived from biochemicals is an exciting research area. Biopolymers provide a sustainable and eco-friendly option for tank manufacturing, reducing reliance on fossil-based materials. Additionally, biopolymer-based tanks can be designed to be recyclable, further enhancing the sustainability of hydrogen storage systems.

Conclusion

To conclude, regenerative fuel cell-electrochemical hydrogen compressor systems present a promising solution for the future of hydrogen and fuel cells. However, continuous research and development are necessary to overcome the challenges and fully realize the potential of these integrated systems. Regenerative fuel cell systems will play a pivotal role in reducing greenhouse gas emissions and achieving a carbon-free economy, contributing significantly to a sustainable energy future.

Taken from Adeerus Ghayan’s book Orycycle.

Amazon Link: https://www.amazon.com/dp/B07MDS544V

Also See

Evolution of Hydrogen Storage Tank Technologies from Type I to Type V Systems