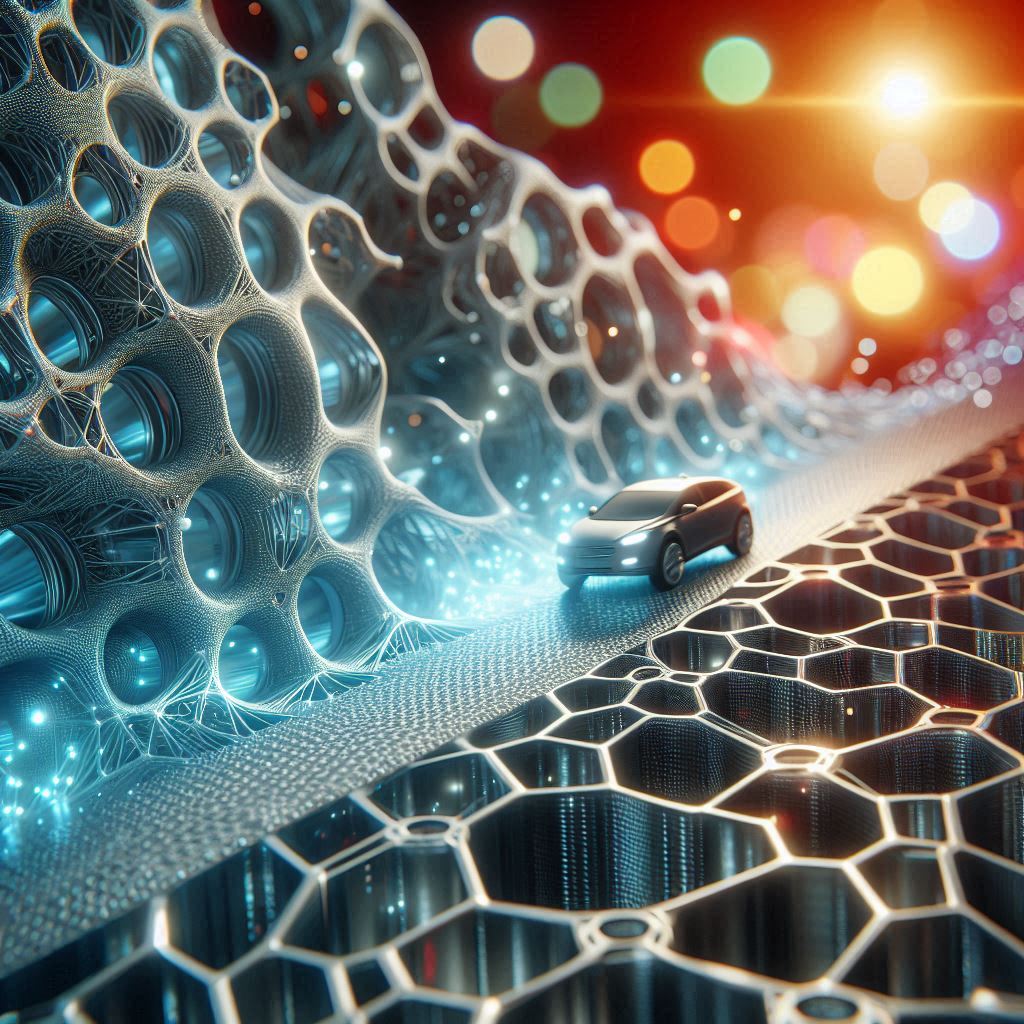

Engineering polymers and composite constitute a vibrant class of materials formed by integrating a polymer matrix with reinforcements—typically fibers, nanoparticles, or other additives—to yield synergistic properties. This fusion allows engineers and scientists to tailor materials at the molecular level, achieving exceptional performance in strength, durability, and thermal stability while maintaining lightweight characteristics. The rising demand for efficiency in hi-tech sectors has prompted extensive research into composite polymers, heralding breakthroughs in nanotechnology, smart sensing, and self-healing functionalities. This article delves into the technical nuances behind these innovations and addresses both their current impact and promising future.

Polymer Matrix Engineering

Contemporary research in polymer chemistry has paved the way for highly crosslinked matrices with tunable properties. Advances in polymerization techniques—such as controlled radical polymerization and click chemistry—have enabled the precise tailoring of molecular weight distributions and network structures. These strategies result in matrices with improved toughness and resistance to environmental degradation, which are critically important for demanding applications like aerospace and automotive components.

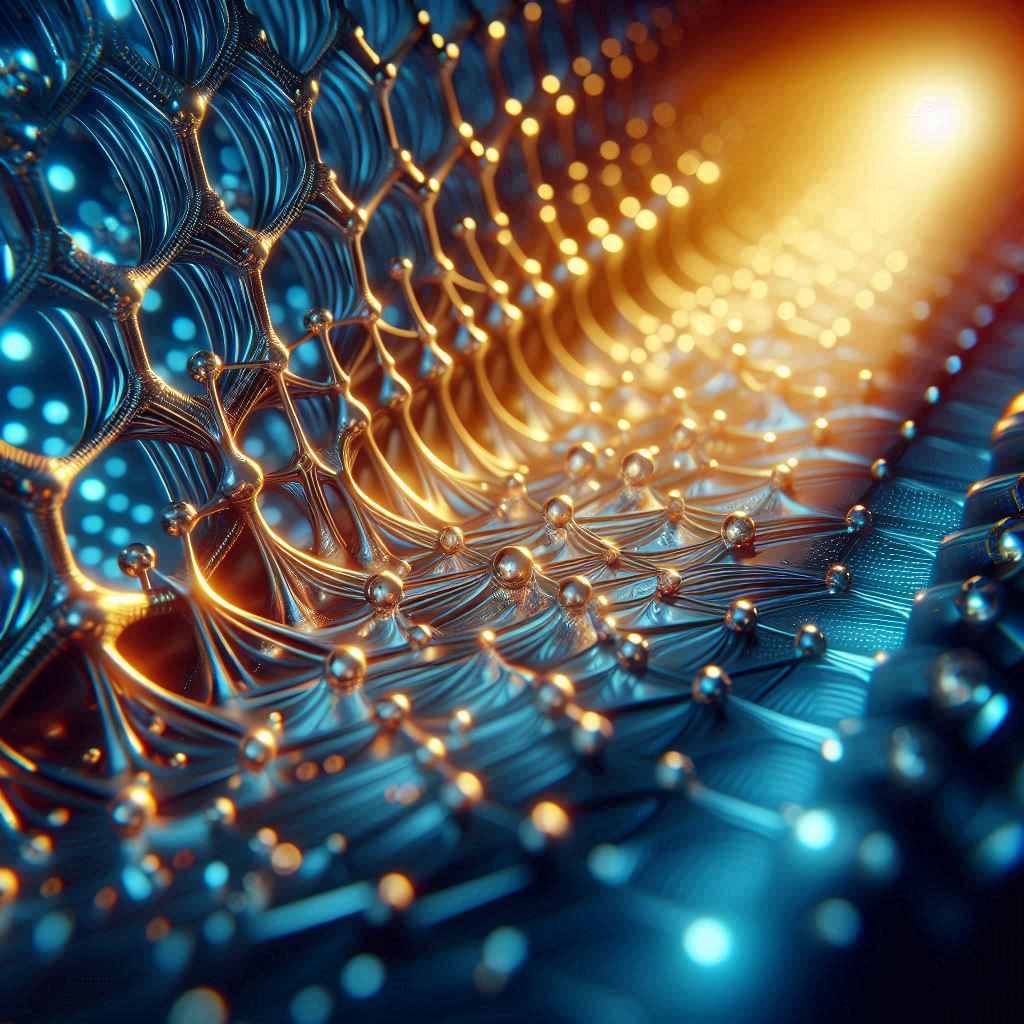

Reinforcement Innovations

The incorporation of advanced reinforcements, such as carbon nanotubes, graphene nanoplatelets, and ceramic nanofibers, has been transformative. For example:

- Carbon Nanotubes and Graphene: These nanomaterials provide unmatched enhancements in electrical and thermal conductance, while also exponentially increasing the tensile strength of the composite. Their integration into polymer matrices yields multifunctional materials that are both lightweight and robust.

- Hybrid Fiber Reinforcements: Combining traditional fibers (like carbon or glass) with emerging nano-reinforcements creates composites that benefit from both macro-scale load distribution and micro-scale performance enhancements. The result is a significant improvement in failure resistance, fatigue behavior, and environmental stability.

Advanced Manufacturing and Simulation

Breakthroughs in additive manufacturing, laser sintering, and automated layup techniques have dramatically improved the processability of composite polymers. Coupled with sophisticated computational modeling and machine learning algorithms, engineers can now optimize composite architectures for tailored performance under complex load profiles. This integration of experimental and digital domains has expedited iterative improvements, reduced prototyping times, and led to more efficient predictive maintenance protocols.

Aerospace and Defense

In modern aerospace engineering, advanced composite and polymers have revolutionized aircraft design, offering unparalleled strength-to-weight ratios, fuel efficiency, and structural integrity. These materials are extensively utilized in fuselages, wing structures, and satellite components, ensuring optimal performance while reducing overall weight.

Lightweight Structural Components

Aircraft manufacturers increasingly rely on composite materials to enhance efficiency and durability. For instance:

- Airbus A350: Utilizing a blend of carbon fiber composites, this aircraft boasts superior aerodynamics and reduced maintenance costs.

- Bell V-280 Valor: A next-generation tiltrotor aircraft featuring thermoplastic composite ruddervators and compression-molded access panels. These materials reduce weight, improve durability, and enhance production efficiency, making the V-280 one of the first military aircraft to incorporate thermoplastic components.

- Boeing 787 Dreamliner: Constructed with carbon fiber-reinforced polymer (CFRP), this aircraft achieves a remarkable 20% increase in fuel efficiency compared to traditional aluminum-based designs.

- Irkut MC-21: Features composite wings, improving lift-to-drag ratios and overall flight performance.

Stealth and Impact Resistance in Defense Applications

In military aviation, specialized composites integrated with radar-absorbing materials and ballistic-resistant layers enhance survivability in hostile environments. Notable examples include:

- F-35 Lightning II: Employs carbon fiber composites and radar-absorbing materials, significantly reducing its radar cross-section for stealth operations.

- B-2 Spirit Bomber: Designed with advanced polymer composites, enabling superior stealth capabilities and operational endurance.

The integration of composite polymers in aerospace engineering continues to push the boundaries of innovation, ensuring safer, more efficient, and technologically advanced aircraft for both commercial and defense applications.

Automotive Industry

In the relentless pursuit of fuel efficiency and emissions reduction, automakers are increasingly replacing conventional metals with advanced composite materials. These lightweight yet durable materials significantly reduce vehicle weight, thereby improving fuel economy and lowering greenhouse gas emissions. Additionally, the integration of additive manufacturing with polymer composites has revolutionized the production of customized, crash-optimized components, enhancing both safety and performance.

Fuel Efficiency and Emissions Reduction

The use of carbon fiber-reinforced polymer (CFRP) and glass fiber-reinforced polymer (GFRP) in automotive design has led to substantial improvements in efficiency:

- BMW i3: Constructed with a CFRP passenger cell, this electric vehicle achieves superior energy efficiency while maintaining structural integrity.

- Chevrolet Corvette C8: Utilizes carbon fiber composites in its body panels, reducing weight and enhancing aerodynamics.

- McLaren P1: Features a carbon fiber monocoque, optimizing performance and fuel consumption.

3D Printed and Customized Components

The integration of additive manufacturing with polymer composites has enabled the production of complex, lightweight parts tailored for crashworthiness and energy absorption:

- Bugatti Chiron: Employs 3D-printed titanium brake calipers, reducing weight while maintaining exceptional strength.

- Koenigsegg Jesko: Utilizes carbon fiber-reinforced polymer (CFRP) chassis, enhancing rigidity and impact resistance.

- Ford Shelby GT500: Features 3D-printed nylon and carbon fiber components, optimizing aerodynamics and durability.

As automotive engineering continues to evolve, advanced composites remain at the forefront of innovation, driving efficiency, sustainability, and safety in next-generation vehicles.

Robotics, Androids, and Drones

The integration of high-performance composite materials into robots, androids, and drones has revolutionized their efficiency, durability, and adaptability. These materials offer lightweight strength, impact resistance, and thermal stability, enabling autonomous systems to perform complex tasks with precision and reliability.

Robotics: Enhancing Agility and Structural Integrity

Robots require lightweight yet robust materials to optimize mobility, endurance, and mechanical performance. Some widely used composites include:

- Carbon Fiber-Reinforced Polymer (CFRP): Used in robotic arms and exoskeletons, offering high stiffness and low weight for precise movements.

- Kevlar-Aramid Composites: Applied in industrial robots, ensuring impact resistance and durability in harsh environments.

- Glass Fiber-Reinforced Epoxy (GFRP): Utilized in autonomous robotic platforms, providing corrosion resistance and structural stability.

Androids: Mimicking Human Motion with Advanced Materials

Humanoid robots require flexible yet strong materials to replicate human-like movement while maintaining structural integrity:

- Silicone-Based Fiber Composites: Used in soft robotics and artificial skin, ensuring elasticity and tactile sensitivity.

- Shape-Memory Polymer Composites: Integrated into adaptive joints and actuators, enabling self-adjusting movement.

- Graphene-Infused Conductive Polymers: Applied in sensor-equipped androids, enhancing electrical conductivity for real-time feedback.

Drones: Lightweight Durability for Aerial Performance

Drones demand high-strength, lightweight composites to maximize flight efficiency and payload capacity:

- Carbon Fiber-Reinforced Thermoplastics (CFRTP): Used in drone frames, ensuring high strength-to-weight ratios for extended flight endurance.

- Polyetheretherketone (PEEK) Composites: Applied in high-temperature drone components, providing thermal stability and chemical resistance.

- Aramid Fiber-Reinforced Epoxy: Utilized in military UAVs, enhancing ballistic resistance and stealth capabilities.

The integration of advanced composites in robotics, androids, and drones continues to drive technological innovation, ensuring greater efficiency, adaptability, and resilience in next-generation autonomous systems.

Electronics and Thermal Management

As electronic devices become increasingly sophisticated, the demand for electromagnetic interference (EMI) shielding and efficient heat dissipation has surged. Advanced composite materials, integrated with conductive fillers and high thermal conductivity polymers, are revolutionizing microelectronics packaging, ensuring stable operations and longevity for high-speed circuits.

EMI Shielding and Conductive Pathways

Electromagnetic interference can disrupt sensitive electronics, necessitating robust shielding solutions. Advanced composites infused with carbon-based fillers, metal nanoparticles, and conductive polymers provide superior EMI shielding. Notable examples include:

- Polymer-Clay Composites: Used in telecommunications and aerospace electronics, these materials offer lightweight, flexible shielding.

- Carbon Nanotube-Reinforced Polymers: Integrated into automotive control units and medical devices, ensuring minimal signal disruption.

- Graphene-Based Composites: Applied in high-frequency circuits, enhancing conductivity while maintaining structural integrity.

Heat Dissipation in Microelectronics

Efficient thermal management is crucial for preventing overheating in electronic components. High thermal conductivity polymers and composite materials optimize heat dissipation, ensuring device reliability. Examples include:

- Aluminum-Filled Epoxy Composites: Used in power electronics and LED modules, facilitating rapid heat transfer.

- Copper-Infused Polymer Blends: Applied in semiconductor packaging, improving thermal conductivity while reducing weight.

- Carbon Fiber-Reinforced Thermoplastics: Utilized in high-performance computing systems, ensuring stable operations under extreme conditions.

The integration of advanced composites in EMI shielding and heat dissipation continues to drive innovation, enhancing the efficiency and durability of next-generation electronic devices.

Renewable Energy

As the global transition to sustainable energy accelerates, the integration of advanced composite polymers into renewable energy devices has become essential. These materials enhance efficiency, durability, and resilience, ensuring longer-lasting components capable of withstanding dynamic environmental loads. Additionally, lightweight, chemically inert composites play a crucial role in hydrogen storage and battery enclosures, safeguarding energy systems while optimizing performance.

Wind Turbines

The demand for high-performance materials in wind energy applications has led to the widespread adoption of fiber-reinforced composites:

- Glass Fiber-Reinforced Polymer (GFRP): Used in wind turbine blades, offering high strength-to-weight ratios and resistance to fatigue.

- Carbon Fiber-Reinforced Polymer (CFRP): Integrated into next-generation wind turbines, improving aerodynamics and longevity.

Solar Panels

- Ethylene Tetrafluoroethylene (ETFE) Films: Applied in solar panel coatings, replacing traditional glass for enhanced light transmission and durability.

- Polyethylene Terephthalate (PET) Core Composites: Utilized in solar panel structures, reducing weight while maintaining mechanical integrity.

Hydrogen Storage

- Thermoplastic Composite Pipes (Polyphenylene Sulfide – PPS): Used in hydrogen distribution, reducing CO₂ emissions while maintaining structural integrity.

- Carbon Fiber-Wrapped Pressure Vessels—Essential for hydrogen storage tanks, providing high-pressure resistance and lightweight durability.

Batteries

- Glass Fiber-Reinforced Epoxy Composites: Applied in battery enclosures, enhancing thermal stability and impact resistance.

- Polyvinylidene Fluoride (PVDF) Insulation Layers: Integrated into lithium-ion battery casings, improving heat dissipation and fire resistance.

The integration of advanced composites in renewable energy systems continues to drive innovation, ensuring greater efficiency, sustainability, and resilience in the global energy landscape.

Biomedical Engineering

The integration of advanced composite polymers into biomedical applications has revolutionized implants, prosthetics, and tissue engineering scaffolds, offering biocompatibility, mechanical adaptability, and enhanced durability. These materials mimic the dynamic behavior of biological tissues, ensuring optimal performance and longevity in medical devices.

Implants and Prosthetics

Load-bearing implants and prosthetic devices require materials that seamlessly integrate with the human body while maintaining structural integrity. Some widely used composites include:

- Ultra-High Molecular Weight Polyethylene (UHMWPE) Reinforced with Carbon Fibers: Used in hip and knee joint replacements, offering low friction and wear resistance.

- Polyetheretherketone (PEEK) Composites: Applied in spinal implants and cranial prosthetics, providing high strength and radiolucency for MRI compatibility.

- Silicone-Based Fiber-Reinforced Composites: Utilized in prosthetic limbs, ensuring flexibility and comfort for long-term use.

- Hydroxyapatite-Reinforced Polymers: Integrated into dental implants, promoting osseointegration and bone regeneration.

Tissue Engineering Scaffolds

Tissue engineering scaffolds are designed to support cell attachment, proliferation, and tissue regeneration. Researchers have developed polymer matrices infused with bioactive fillers to enhance healing:

- Polylactic Acid (PLA) and Polyglycolic Acid (PGA) Blends: Used in biodegradable scaffolds, facilitating **gradual tissue replacement.

- Chitosan-Based Composites: Applied in wound healing and cartilage regeneration, offering antimicrobial properties and biocompatibility.

- Gelatin-Hydroxyapatite Hybrid Scaffolds: Promote bone tissue growth, ensuring strong mineralization and structural support.

- Collagen-Polycaprolactone (PCL) Nanocomposites: Utilized in skin grafts and soft tissue repair, mimicking natural extracellular matrices.

The integration of advanced composites in biomedical engineering continues to drive innovation, ensuring safer, more effective, and long-lasting medical solutions for patients worldwide.

Emerging Trends and Future Perspectives

The field of advanced composite polymers is undergoing rapid transformation, driven by breakthroughs in self-healing materials, smart multifunctional systems, and sustainable innovations. These advancements are set to redefine industrial standards, enhancing durability, adaptability, and environmental responsibility across multiple sectors.

Self-Healing Composites: Autonomous Damage Repair

Researchers are pioneering self-healing composites that can autonomously repair microcracks, extending their operational lifetimes. Some notable developments include:

- Microcapsule-Based Epoxy Composites: Encapsulated healing agents within epoxy resin matrices rupture upon damage, releasing polymeric adhesives to restore structural integrity.

- Diels-Alder Reaction-Based Thermosetting Polymers: Utilizing reversible covalent bonding, these materials enable repeated self-repair cycles, ideal for aerospace and automotive applications.

- Supramolecular Polymer Networks: Incorporating hydrogen bonding and ionic interactions, these composites exhibit dynamic self-healing properties, making them suitable for wearable electronics and biomedical implants.

Smart and Multifunctional Composites

The integration of sensors, actuators, and wireless communication modules within composite matrices is enabling real-time monitoring and adaptive reconfiguration:

- Piezoelectric Fiber-Reinforced Composites: Embedded lead zirconate titanate (PZT) fibers generate electrical signals in response to mechanical stress, enhancing structural health monitoring in aircraft and bridges.

- Shape-Memory Polymer Composites: Incorporating polyurethane-based shape-memory polymers, these materials adjust their form in response to temperature or stress, ideal for deployable aerospace structures.

- Graphene-Infused Conductive Composites: Used in flexible electronics, these materials enable real-time data transmission and energy harvesting.

Sustainable Composites: Eco-Friendly Innovation

The push for environmental sustainability is driving the development of recyclable, bio-based polymers with performance metrics comparable to conventional composites:

- Polylactic Acid (PLA)-Based Biocomposites: Derived from corn starch, these materials offer biodegradability while maintaining mechanical strength, widely used in packaging and medical implants.

- Natural Fiber-Reinforced Epoxy Composites: Incorporating flax, hemp, and jute fibers, these composites provide high strength-to-weight ratios with minimal environmental impact, ideal for automotive and construction applications.

- Lignin-Based Carbon Fiber Composites: A sustainable alternative to petroleum-derived carbon fibers, these materials enhance lightweight structural components in wind turbines and aerospace systems.

The future of advanced composite polymersis poised for groundbreaking innovation, ensuring greater resilience, intelligence, and sustainability across industries. As research continues to evolve, these materials will play a pivotal role in shaping next-generation technologies.

Conclusion

Advanced composite polymers embody a fusion of material science ingenuity and engineering precision, offering unprecedented advantages across a myriad of hi-tech applications. From aerospace components to biomedical devices, they herald a new era where high performance, sustainability, and smart functionalities converge. Continued research and interdisciplinary collaboration will undoubtedly propel these materials into future realms of technological possibility, making advanced composite polymers the cornerstone of tomorrow’s innovations.