The global demand for sustainable, low-carbon energy sources has never been more critical. The traditional reliance on fossil fuels—with all its associated environmental ramifications—has spurred intensive research into renewable alternatives, positioning bioethanol as a promising candidate in the renewable energy portfolio. As the biofuel expert community has long debated, the evolution of bioethanol production is not merely a technological progression but also a systemic shift toward a more sustainable energy economy. This review examines the historical development and technological maturation of bioethanol production, elaborating on the distinct generations, their developmental challenges, and the integrative approaches that promise to reconcile economic feasibility with environmental stewardship.

First-Generation Bioethanol: The Foundational Era

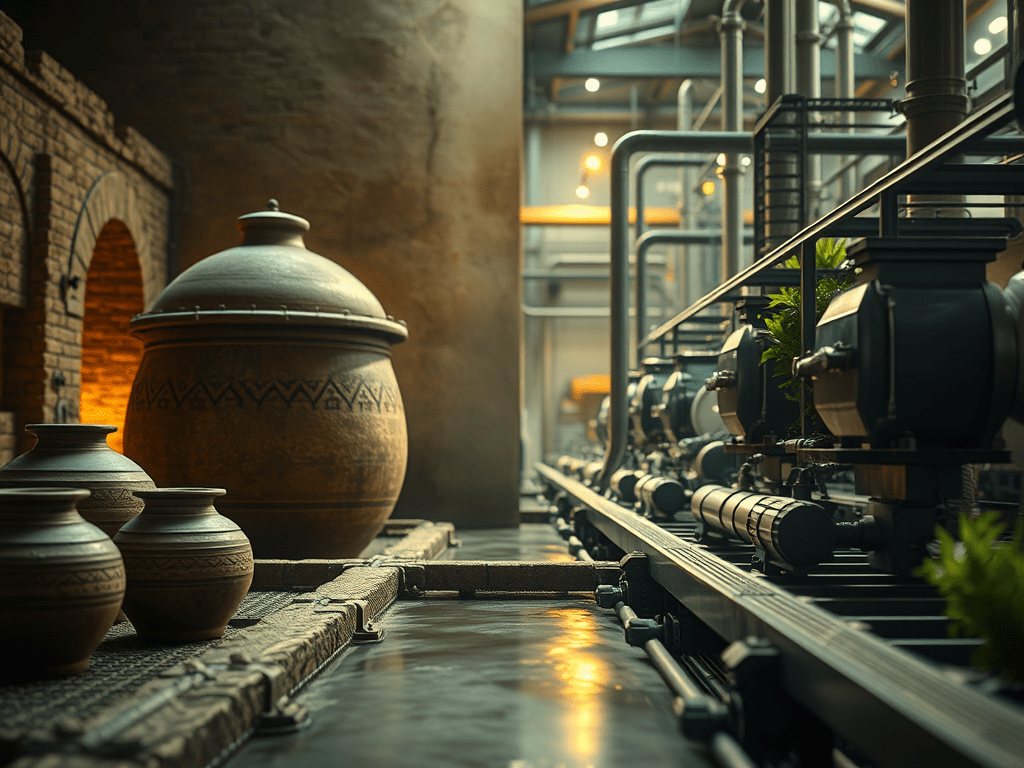

The story of ethanol production is as ancient as civilization itself. Archaeological evidence from early Neolithic sites—such as ceramic vessels from Jiahu, China, dating back over 7,000 years—indicates that early humans discovered fermentation, harnessing naturally occurring sugars to produce alcoholic beverages for ritualistic, medicinal, and culinary purposes. Ancient cultures in Mesopotamia and Egypt further refined these rudimentary techniques, laying the cultural and scientific groundwork for controlled fermentation, a process whose principles were later elucidated by pioneers like Louis Pasteur during the 19th century.

This long history of fermentation eventually converged with modern energy demands, giving rise to first-generation bioethanol. Emerging as a straightforward solution to fossil fuel dependency, first-generation bioethanol harnesses fermentable sugars and starches derived from edible crops—such as corn, sugarcane, wheat, and barley—to produce ethanol through well-established microbial fermentation processes. Its rapid global acceptance owes much to simplicity, scalability, and the immediate impact on energy portfolios, all built upon millennia of fermentation expertise.

However, the reliance on food-based feedstocks has inevitably sparked ethical and environmental debates, notably the “food-versus-fuel” conflict. Concerns over the diversion of critical agricultural resources, extensive land use, water consumption, and biodiversity loss underscore the complex trade-offs inherent in this technology. Despite these challenges, the advent of 1G bioethanol production did more than simply provide a renewable fuel alternative—it established the technical, regulatory, and economic frameworks that underpin modern biofuel markets. In doing so, it transformed ancient artisanal methods into a sophisticated, industrial-scale technology that has paved the way for subsequent generations of bioethanol innovations.

Second-Generation Bioethanol: Advancing Sustainability with Lignocellulosic Biomass

In pursuit of sustainable alternatives that bypass the food-versus-fuel issue, the second generation of bioethanol technology pivoted toward lignocellulosic biomass derived from agricultural residues, forestry by-products, and even municipal solid waste. This transition necessitated the development of advanced pretreatment and enzymatic hydrolysis methods to break down the recalcitrant plant cell wall polymers into fermentable sugars. Though 2G technologies face inherent challenges—such as high processing costs, complex feedstock variability, and the need for robust catalytic systems—the potential benefits are transformational. By harnessing a vastly underutilized resource base, 2G bioethanol offers the dual promise of reduced ecological footprint and enhanced energy security, while integrating seamlessly into the broader concept of a biorefinery that produces a suite of value-added products alongside fuel.

Third-Generation Bioethanol: The Frontier of Algal and Advanced Biotechnologies

The advent of third-generation bioethanol represents a paradigm shift in renewable energy production, capitalizing on the extraordinary metabolic versatility of microalgae and genetically engineered microorganisms. Unlike their 1G and 2G predecessors, 3G systems exploit non-traditional feedstocks that do not compete with food resources, often utilizing non-arable land, brackish water, or even industrial effluents. Innovations in synthetic biology, metabolic engineering, and precision cultivation techniques have increased yield efficiencies to previously unattainable levels, while enabling the capture and reuse of CO₂ to further enhance the sustainability of the process. Despite facing challenges in terms of large-scale cultivation logistics, biomass harvesting, and downstream processing, the integration of these transformative approaches with advanced digital control systems and process simulation promises not only to reduce production costs but also to establish a revolutionary, closed-loop system for renewable fuel manufacturing.

Integrated Biorefinery Concepts and Techno-Economic Analysis (TEA)

Modern bioethanol production is increasingly viewed as part of an integrated biorefinery framework, whereby multiple high-value co-products are generated from biomass, enhancing overall process viability and reducing waste. Advanced process integration—including heat and energy recovery systems, diversified product portfolios (such as biochemicals and bio-based materials), and state-of-the-art catalytic conversion methods—has the potential to transform bioethanol production into a highly competitive industrial process. Rigorous techno-economic analyses (TEA), life cycle assessments (LCA), and sustainability metrics underpin these integrated systems, ensuring that future production methods are not only economically sound but also ecologically responsible. Such multidisciplinary approaches are essential for scaling up these technologies to meet the demands of a rapidly evolving global energy landscape.

Policy Implications, Research Directions, and Future Prospects

The evolution of bioethanol production is deeply intertwined with global policy frameworks designed to mitigate climate change and promote renewable energy. Governmental mandates and incentives, such as carbon pricing, renewable fuel standards, and research funding initiatives, have accelerated the development and deployment of advanced bioethanol technologies. Moving forward, pivotal research directions include the optimization of enzymatic efficiency, genetic enhancements for higher biomass yields, improved feedstock preconditioning techniques, and the integration of artificial intelligence and machine learning for process optimization. Additionally, a more harmonized policy environment that fosters multinational collaborations and public-private partnerships will be critical in driving the sustainable scale-up of bioethanol production globally.

Conclusions

The journey from first-generation crop-based bioethanol to second-generation lignocellulosic methods and finally to the cutting-edge third-generation algal and biotechnological systems exemplifies an inspiring evolution in renewable energy. Each technological phase not only addressed the limitations of its predecessor but also set new benchmarks for efficiency, sustainability, and scalability. The convergence of technological innovation, integrated biorefinery concepts, and supportive policy frameworks heralds a promising future for bioethanol production. As the world intensifies its efforts to combat climate change, the continuous evolution of bioethanol, underpinned by rigorous research and technological breakthroughs, will play an indispensable role in securing a resilient, sustainable energy future.

Aslo See

Biogas Anaerobic Digestion: Processes, Technologies, and Industrial Applications

Sustainable Aviation Fuel (SAF) from Biowaste and CO₂ Solving the Food vs Fuel Dilemma